WORK AREAS

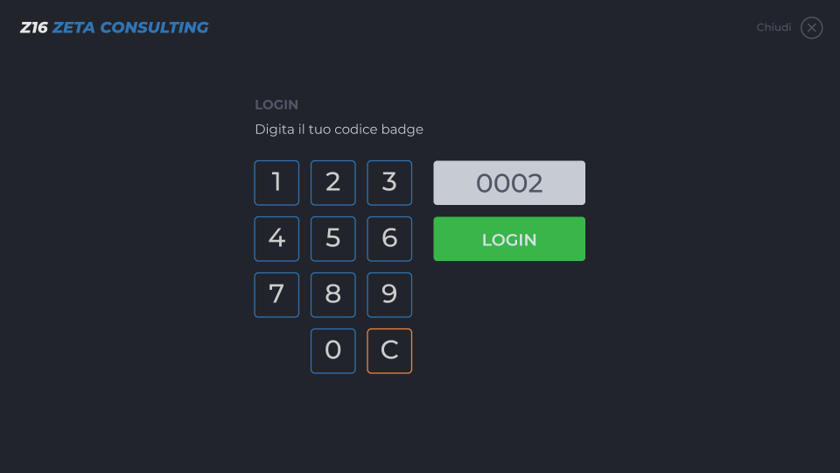

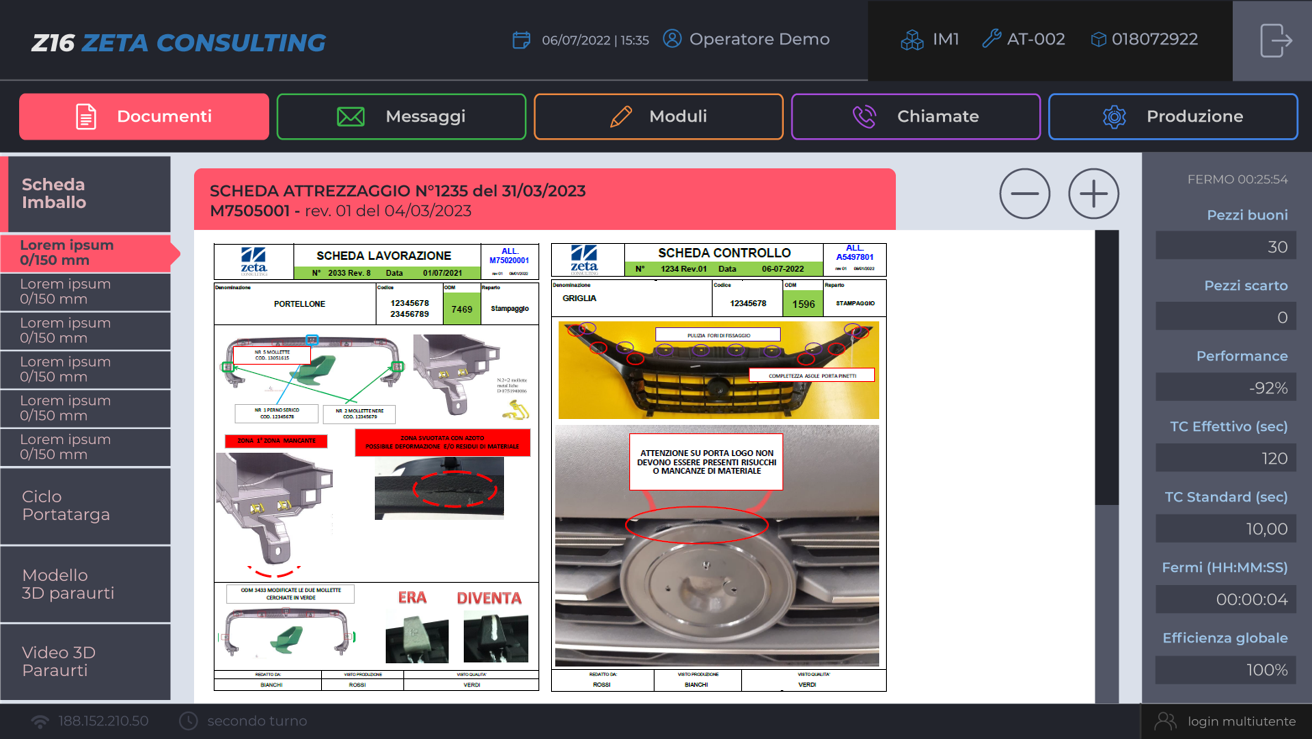

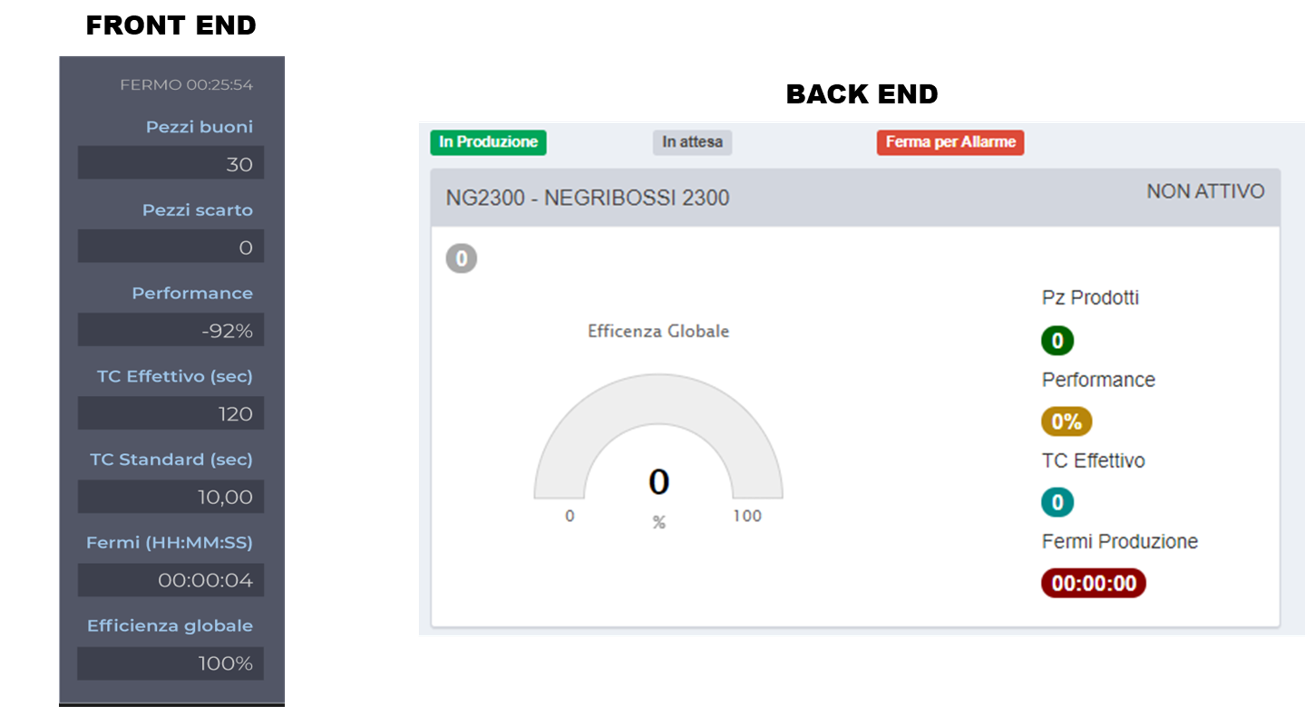

FRONT END

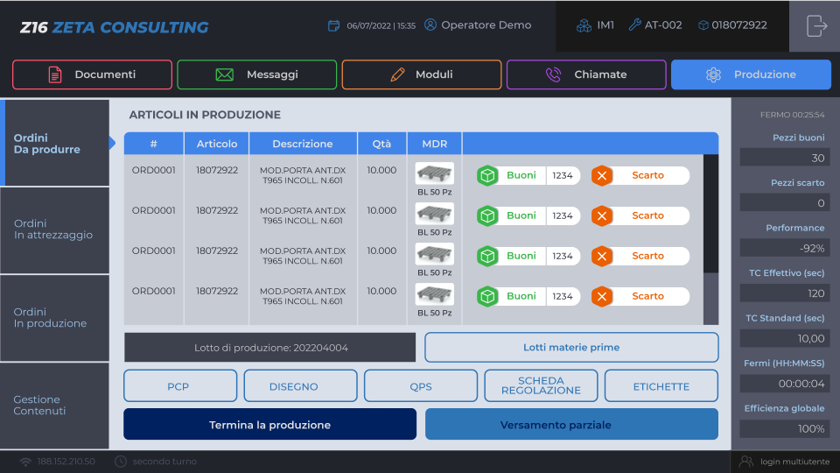

Dedicated primarily to line operators, it exposes a series of dashboards and sections to manage plant-side activities

BACK END

Dedicated to various managers, enables configuration, management, submission, and historization of content and process controls

SECTIONS

MODES OF INTERCONNECTION

Plant 4.0 ready

Interconnection to industrial plants 4.0 ready viaSoftware Gateway for interfacing with industrial plants.

The KEPServerEX solution offers the widest range of drivers available (+100 drivers) supporting almost all devices in the used industrial automation sector.

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11a

- 11b

- 12

- 13

- 14

- 15

-

-

- ACCESS DOCUMENT SECTION

Access to the document section and verification of reference checklists -

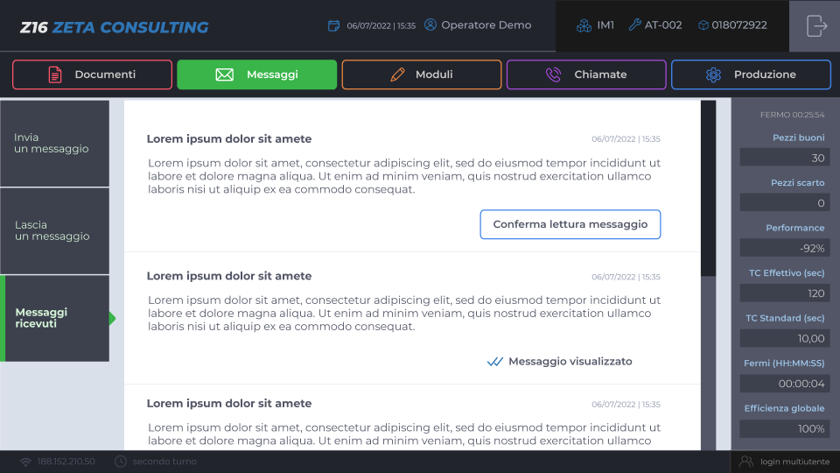

- READING AND REPLYING MESSAGES

Access to the messaging section and ability to read write messages -

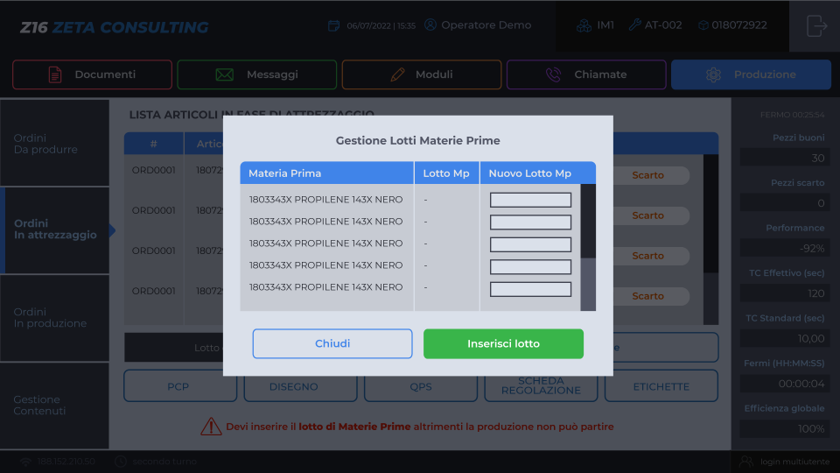

- RAW MATERIAL BATCH MANAGEMENT

Selection and batch management of raw material for production to monitor and ensure traceability of raw materials -

-

-

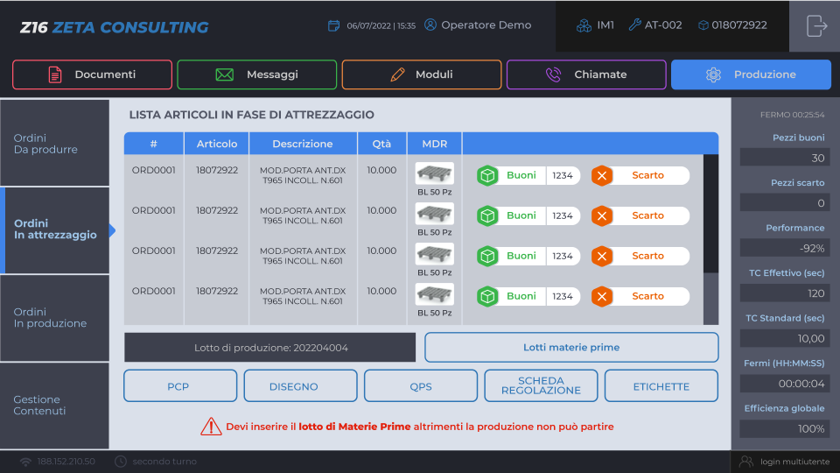

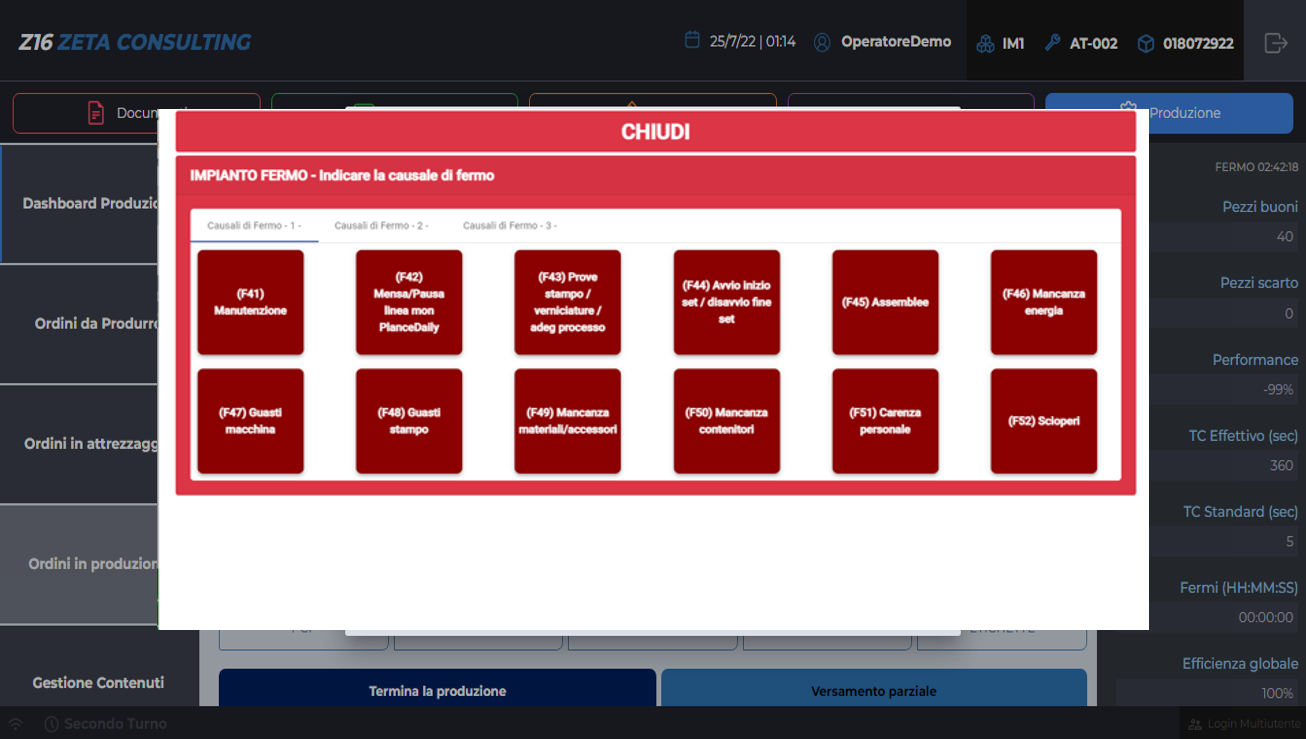

- MANAGEMENT PRODUCTION

Management and monitoring of all activities related to production (e.g. article code to be produced, quantities to be produced, good parts, scrap pieces, …) -

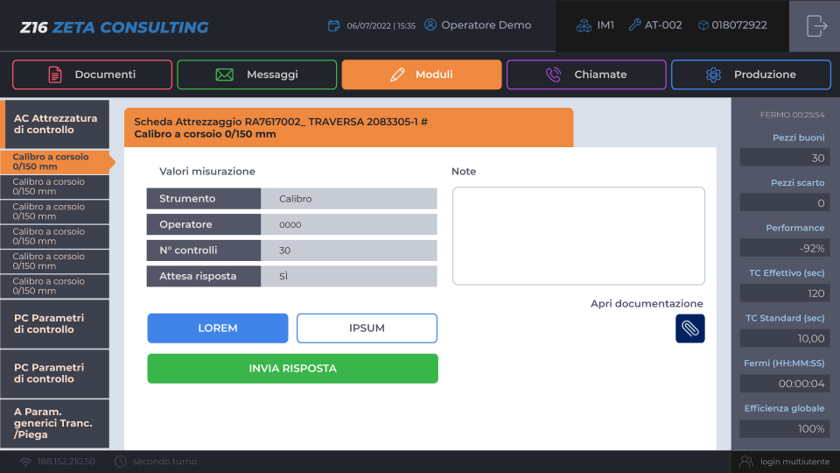

- MANUFACTURING CONTROL

Production control plan management: according to the given specifications, it allows to record spot checks or scheduled checks according to various needs -

-

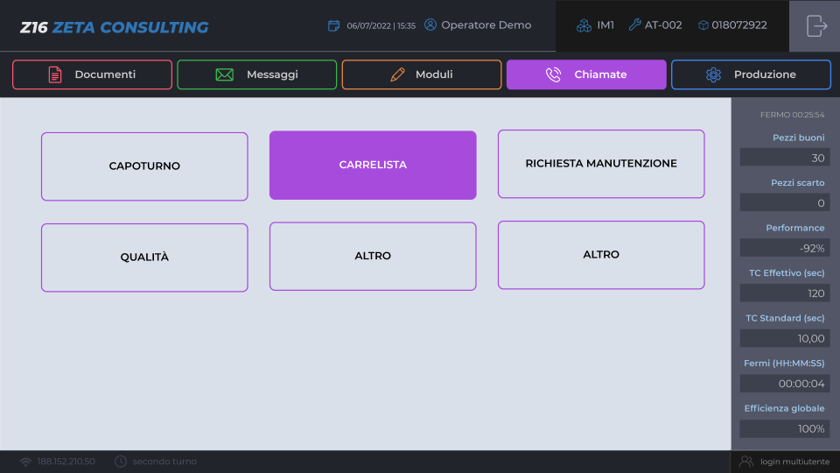

- SERVICE CALL

Possible maintenance call and native link with Tool Z14 – Maintenance Management -

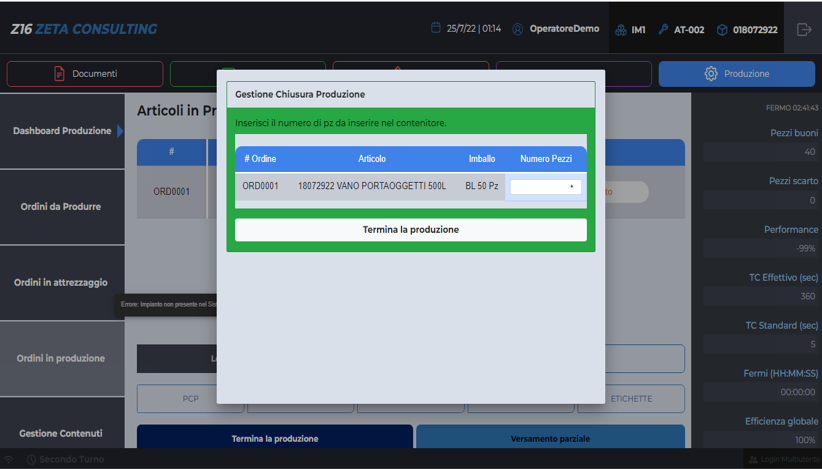

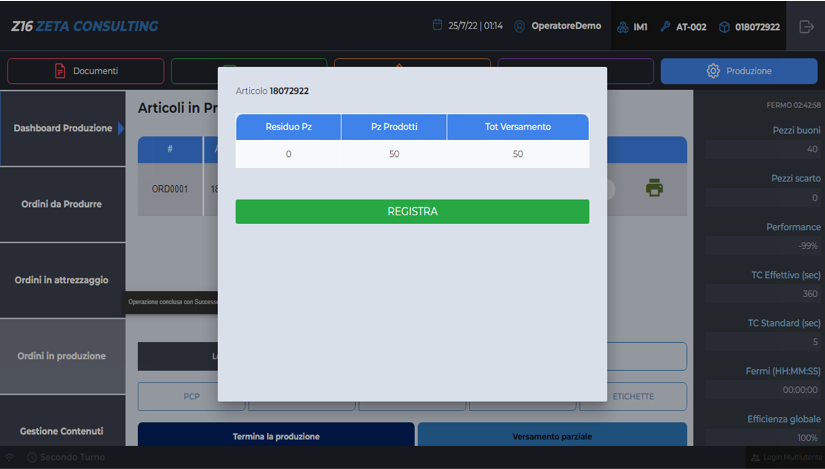

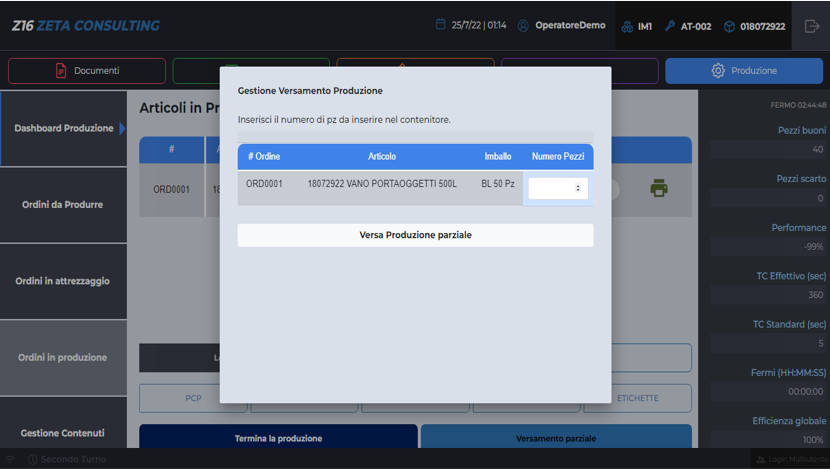

- DECLARATION GOOD PIECES

Statement of good parts. In order to avoid input errors, the system allows you to enter quantities equal to those indicated on the packing slip. Exceptions […] -

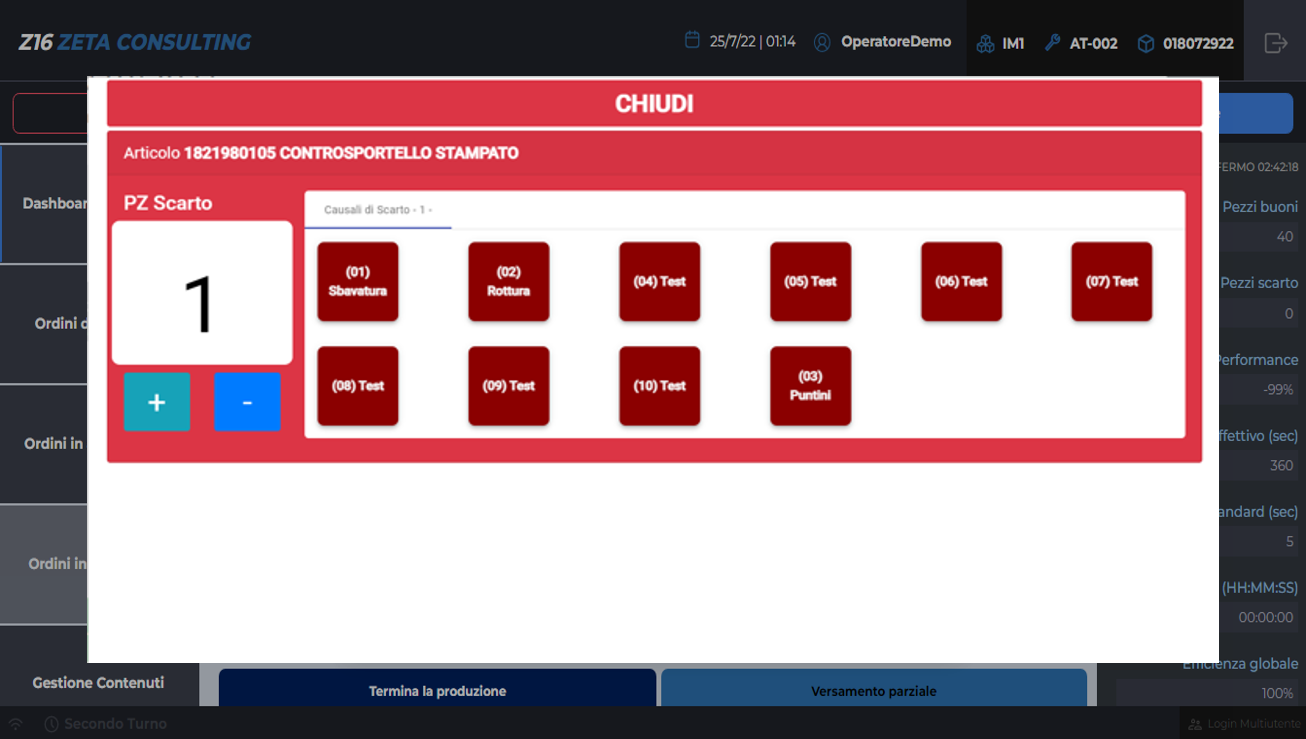

- DISCARD PIECE DECLARATION

Declaration of discarded parts, with entry of the relevant reason (customizable) -

- SHIFT MANAGEMENT

Management of shift change operations and any partial production declarations -

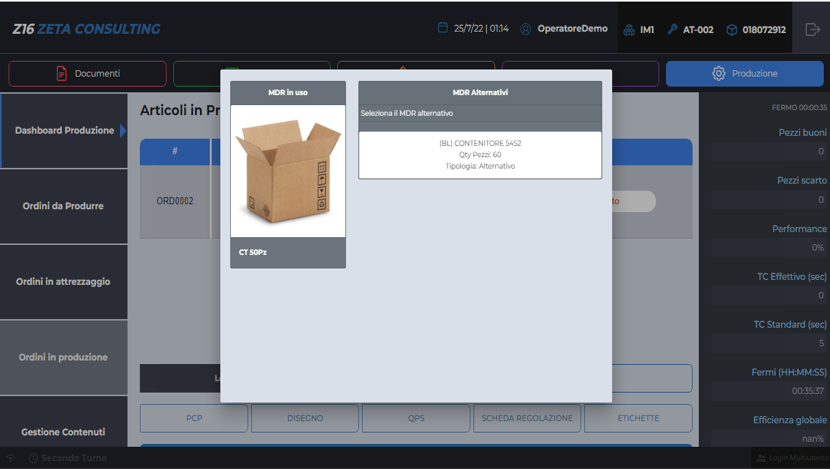

- PACKAGE SELECTION

Management and selection of reference packaging, with the possibility of using alternative packaging cards -

- LABEL PRINT

Printing of the packaging label with the possibility of customization of the format related to the customer/item -

- PERFORMANCE ANALYSIS

Production performance analysis with visibility to both front end and back end